The 5th National Annual Conference on Innovation and Development of Prefabricated Mechanical and Electrical Engineering is guided by the China Equipment Management Association and co-organized by the Prefabricated Mechanical and Electrical Engineering Committee of the China Equipment Management Association, Shenzhen General Institute of Architectural Design and Research Co., Ltd., and Shenzhen Municipal Design Institute Co., Ltd.

The "Jinan Dongcheng Comprehensive Smart Heat Source Project (Phase II CHRS System Deepening Design)" submitted by Meide Group stood out among more than 250 submitted projects and won the first prize in the design group. BIM design engineer Sun Qizhi won the honorary title of "Design Application Technology Expert", which fully demonstrated the professional strength of Meide Group in the design and installation of prefabricated electromechanical fields. The company's innovative R&D capabilities, project management capabilities, and one-stop solution provision capabilities were fully recognized by the leaders present, enhancing its brand influence in the prefabricated electromechanical field.

The award-winning application topic is an in-depth technical study of the pipeline prefabrication and processing of the Jinan Dongcheng Comprehensive Smart Heat Source Project (Phase II CHRS System) in which the company participated. This project is a key project in Jinan and a major livelihood project, which is of great significance to helping Jinan achieve its dual carbon goals.

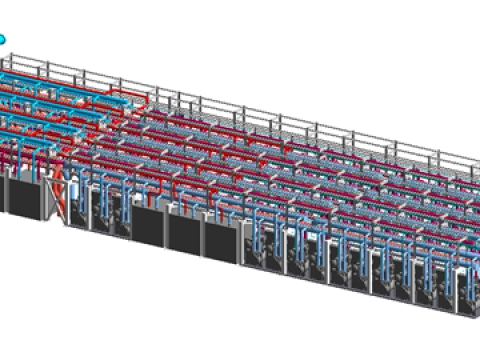

The project focused on the research on factory production and on-site rapid assembly technology of large-diameter internal and external plastic-coated pipelines in high-temperature application scenarios through the application of BIM technology, thereby shortening the construction period, improving construction efficiency and reducing material loss.

1. BIM technology + system optimization design

Through BIM design, the pipeline system can be rationally disassembled and prefabricated in the factory, which solves problems such as construction guidance and data consistency management, and improves the overall efficiency and quality of the project.

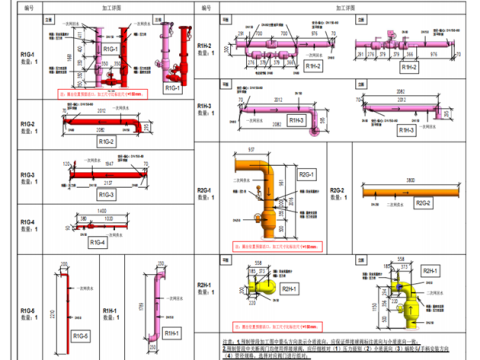

2. Accurate prefabrication of processing drawings

1) Use BIM technology to achieve a three-dimensional effect and visually display the location of components.

2) Pre-fabricate processing drawings to accurately calculate the processing dimensions of each component to reduce losses.

3) By numbering the pipe sections, the construction site is guided to install quickly, and the installation efficiency is increased by more than 30%.

Meide Group focuses on pipeline technology and explores pipeline prefabrication. It leads the market with technology, expands its advantages with innovation, demonstrates product quality with service, and provides customer-centric overall prefabricated solutions.

VIE

VIE EN

EN