In the field of gas transportation, safety and corrosion prevention are two crucial core elements. With its profound technical accumulation and innovative strength, the Meide Group has carefully crafted wide-edge malleable cast iron gas pipe fittings, setting a new industry benchmark in terms of safety and corrosion resistance, and safeguarding the stable operation of gas transportation.

1. Safety first, all-round protection

(i) Innovative wide edge design to eliminate leakage risks

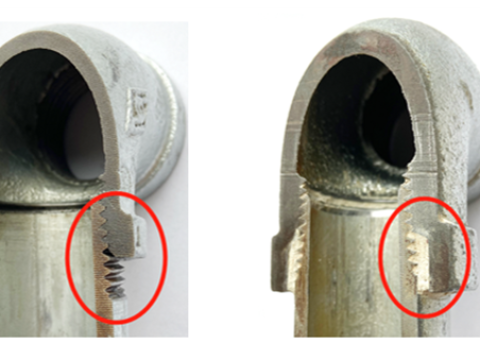

Different from traditional pipe fittings, the wide-edge malleable cast iron gas pipe fittings of Meide adopt a breakthrough wide-edge structure, which can cover all threads tightly and completely hide them. This design fundamentally eliminates the risk of gas leakage caused by exposed threads due to wear and looseness during long-term use. Compared with ordinary gas pipe fittings, when connecting steel pipes, 2-3 threads are exposed, and the safety of Meide pipe fittings has been qualitatively improved.

(ii) Special sealant to enhance the sealing effect

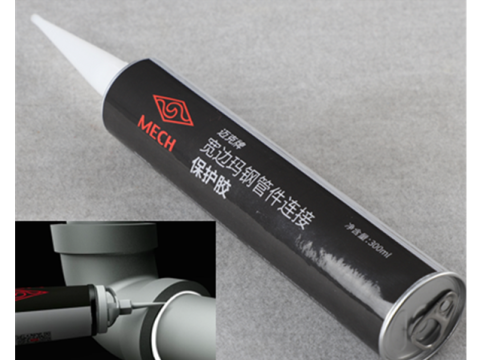

Meide Group has independently developed a special adhesive that has strong adhesion and anti-aging properties. When connecting pipes, the special adhesive is filled between the wide edge and the thread, further enhancing the sealing of the connection, just like adding a solid "safety lock" to the gas transmission channel, greatly reducing the possibility of gas leakage.

2. Excellent anti-corrosion and long-lasting durability

(i) Salt spray test witnesses, outstanding anti-corrosion strength

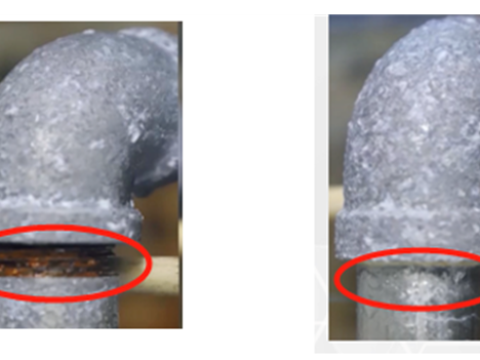

In the strict neutral salt spray test, the wide-edge malleable cast iron gas pipe fittings of Meide performed amazingly, with no signs of rust after 1,400 hours. Under the same test conditions, ordinary malleable cast iron pipe fittings showed red rust in just 24 hours, and the difference in anti-corrosion performance between the two was immediately apparent. This outstanding result fully demonstrates the strong corrosion resistance of Meide pipe fittings, which can maintain good performance for a long time even in harsh environments, greatly extending their service life.

(ii) Advanced hot-dip galvanizing technology to build long-term protection

The pipe fittings are made by advanced hot-dip galvanizing process to form a dense zinc-iron alloy layer on their surface. This alloy layer not only has excellent corrosion resistance, but also has excellent adhesion and strong resistance to knocks. It can effectively resist the erosion of oxygen, moisture and various corrosive media in the air to the pipe body, like a solid "armor", providing lasting protection for the pipe fittings.

(iii) Comprehensive protection of threads to prevent local corrosion

3. Product types and parameters

Note: Product details can be viewed on the official website of Meide Group ( https://www.meide-casting.com/).

4. Choose Meide, choose peace of mind

Today, as gas safety and facility durability are increasingly valued, the wide-edge malleable cast iron gas pipe fittings of the Meide Group are undoubtedly your ideal choice. We are committed to providing safe, reliable and efficient gas transportation solutions to users around the world with excellent quality and innovative technology. Choosing Meide means choosing peace of mind, so that you don't have to worry about gas leakage and pipe corrosion, and enjoy a convenient and safe gas life.

If you are interested in our wide-edge malleable cast iron gas pipe fittings, please feel free to contact us. We will serve you wholeheartedly and work together to build a safer and more reliable future for gas transportation.

VIE

VIE EN

EN